Merchandising

Communication which is the key in every business and our team provide clear and transparent response to the needs of the customer and solves their queries immediately.

Reporting And Communication

Our company is well equipped with very strong communication system supporting the buyers in by providing daily status of the merchandise, progress of orders with absolute clarity in process Management

Sampling

We have a highly experienced pattern technician capable of handling different styles. We can develop any type of samples as per your requirement within stipulated time or if need be expedite within two weeks’ time frame

Cutting

Qc team are involved in this area. First quality team inspects the griege fabric and then sent for dyeing and finishing. On arrival of the fabric it is inspected for flaws like colour fastness,dimension stability,dye patches and after Qc team reporting to the QC manager the bulk cutting is done and cut parts are checked and then assembled and kept together in batch lots throughout production.

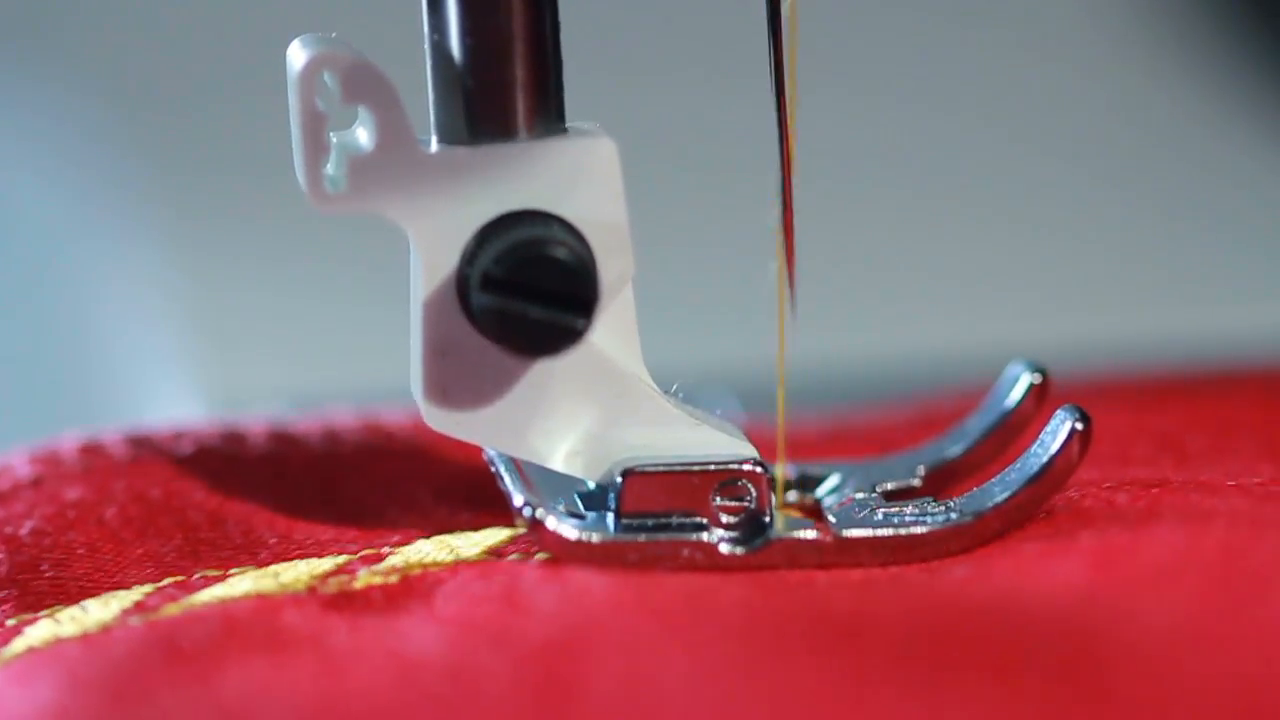

Stitching & Finishing

In-Line Quality Control.

A sealed samples hangs in the main stitching area for comparison purpose.

2 Inspectors oversee stitching and check production on random basics.

Final Quality Control.

After trimming quality control people check the garments and apply a personal quality Control sealed to the garments they have approved, After hand ironing the garments are packed.

Final Inspections

Random test are carried out on the final inspection..

Factory Machineries Details

Over lock Machines.

Flat Lock Machines.

Single needle machines.

Band Knife.

Straight Knife and End Cutter machines.

Ironing Table.

Stain Remover.

Capacity: 30000 units (per month) plus / minus depending on the product.

Compliances

Our company will be with compliances by WRAP & SEDEX. ( In process)